This post contains affiliate links. This means I will make a commission at no extra cost to you should you click through and make a purchase [ “As an Amazon Associate, I earn from qualifying purchases.” ]. Read the full disclosure here.

Understanding the P0008 Code: Engine Position System Performance Bank 1 GuideMechanic.Com In the intricate network of a vehicle’s engine management system, precise timing and positioning are crucial for optimal performance.

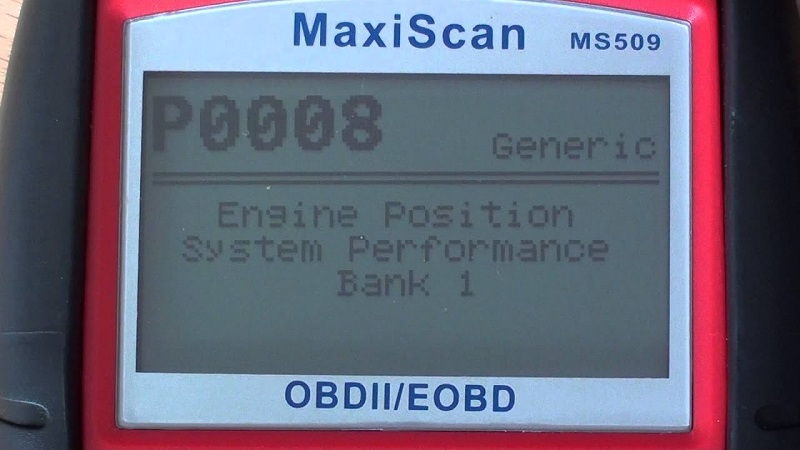

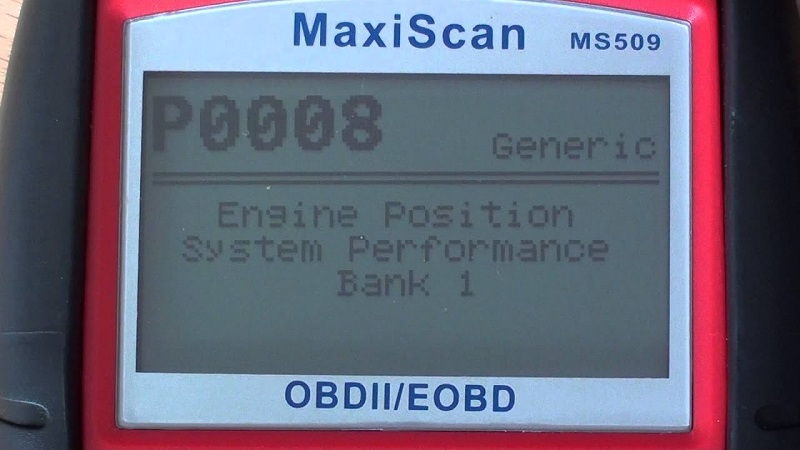

When an issue arises with the engine position system, it can lead to significant performance problems. The P0008 trouble code specifically relates to engine position system performance on Bank 1.

This article aims to decode what the P0008 code means, explore its potential causes, and outline the necessary steps to resolve it effectively.

See Also: P0007 Code: Fuel Shutoff Valve ‘A’ Control Circuit High

Deciphering the P0008 Code:

The P0008 trouble code is an OBD-II diagnostic code that indicates a fault in the engine position system’s performance on Bank 1. Bank 1 refers to the side of the engine that contains cylinder 1 in vehicles with multiple banks of cylinders.

The engine position system, also known as the camshaft position system, is responsible for synchronizing the rotation of the camshaft(s) with the crankshaft, ensuring proper timing of valve operation and fuel injection.

When this fault occurs, the engine control module (ECM) detects a discrepancy between the expected position of the camshaft(s) and the actual position. This misalignment can lead to various performance issues, including reduced power, rough idling, and even engine stalling.

Potential Causes:

Several factors could contribute to triggering the P0008 code, including:

Timing Chain or Belt Issues:

Problems with the timing chain or belt, such as stretching, skipping teeth, or complete failure, can lead to a misalignment between the camshaft(s) and crankshaft, triggering the P0008 code.

Faulty Camshaft Position Sensor:

The camshaft position sensor is responsible for monitoring the position of the camshaft(s). A faulty sensor can provide inaccurate data to the ECM, leading to timing discrepancies and the P0008 code.

Engine Oil Issues:

Insufficient or contaminated engine oil can affect the operation of components involved in the engine position system, such as the timing chain/belt tensioner or variable valve timing (VVT) components, resulting in timing irregularities.

Damaged Components:

Damage to components such as the camshaft(s), crankshaft, or timing chain/belt sprockets can lead to mechanical issues that affect timing and trigger the P0008 code.

ECM Software or Hardware Problems:

In rare cases, software glitches or hardware failures within the ECM itself can cause erroneous readings and trigger fault codes like P0008.

P0008 Code: Engine Position System Performance Bank 1

Symptoms:

When the P0008 code is triggered, drivers may experience various symptoms, including:

Check Engine Light:

The illumination of the check engine light on the vehicle’s dashboard is the primary indicator of a problem.

Engine Performance Issues:

See Also: P0006 Code: Fuel Shutoff Valve “A” Control Circuit Low

Reduced power, rough idling, hesitation, or stalling may occur due to timing irregularities.

Abnormal Engine Sounds:

Rattling, ticking, or grinding noises from the engine may indicate mechanical issues related to the timing system.

Decreased Fuel Efficiency:

Timing discrepancies can lead to inefficient fuel combustion, resulting in reduced fuel efficiency.

P0008 Code: Engine Position System Performance Bank 1

Diagnostic Procedure:

Diagnosing the underlying cause of the P0008 code typically involves a systematic approach, including:

Code Scan:

Using an OBD-II scanner to retrieve the trouble code and any accompanying codes can provide valuable diagnostic information.

Visual Inspection:

Inspecting the timing chain or belt, camshaft(s), crankshaft, and associated components for signs of wear, damage, or misalignment.

Testing Camshaft Position Sensor:

Checking the camshaft position sensor for proper operation and signal consistency using a multimeter or oscilloscope.

Inspecting Engine Oil:

Checking the engine oil level and condition to ensure it meets manufacturer specifications and is free from contamination.

Checking Timing Components:

Verifying the timing chain or belt tension, alignment, and integrity of related components such as tensioners and guides.

P0008 Code: Engine Position System Performance Bank 1

Resolving the Issue:

Check out this Motorcraft DU70 Cam Position Sensor

Once the root cause of the P0008 code has been identified, appropriate steps can be taken to resolve the issue effectively:

Repairing or Replacing Timing Components:

Addressing issues with the timing chain or belt, tensioners, guides, and related components as necessary to restore proper timing.

Replacing Camshaft Position Sensor:

If the camshaft position sensor is faulty, replacing it with a new sensor can resolve timing discrepancies.

Addressing Engine Oil Issues:

Ensuring the engine oil meets manufacturer specifications and addressing any issues with oil level or contamination can prevent future timing problems.

Performing ECM Software Update:

If a software glitch is suspected, updating the ECM software to the latest version may resolve the issue.

Clearing Codes:

After repairs are completed, clearing the trouble codes using an OBD-II scanner allows the ECM to reevaluate the system and monitor for any recurring issues.

Conclusion:

See Also: P0005 Code: Fuel Shutoff Valve “A” Control Circuit/Open

The P0008 code indicating engine position system performance issues on Bank 1 is a critical fault that demands prompt attention to prevent potential engine damage and performance problems.

By understanding the potential causes, symptoms, and diagnostic procedures associated with this code, vehicle owners and technicians can effectively address the issue and restore optimal engine operation.

Regular maintenance, timely repairs, and proper lubrication play crucial roles in ensuring the longevity and reliability of the engine’s timing system.