This post contains affiliate links. This means I will make a commission at no extra cost to you should you click through and make a purchase [ “As an Amazon Associate, I earn from qualifying purchases.” ]. Read the full disclosure here.

Understanding DTC P3402: Cylinder 1 Deactivation/Intake Valve Control Circuit Performance GuideMechanic.Com Modern engines, particularly V6 and V8 engines, are increasingly equipped with cylinder deactivation systems to reduce fuel consumption and emissions during light engine loads.

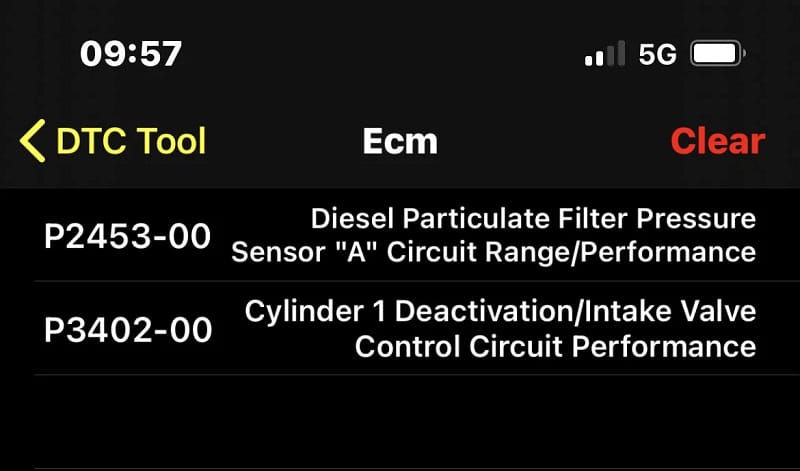

One common Diagnostic Trouble Code (DTC) related to this system is P3402, which refers specifically to a performance issue in the intake valve control circuit for cylinder 1.

This article provides a comprehensive overview of DTC P3402, including how the system works, why the fault code may be triggered, common symptoms, diagnostic steps, and recommended repair strategies.

See Also: P3403 Cylinder 1 Deactivation/Intake Valve Control Circuit Low

P3402 – Cylinder 1 Deactivation/Intake Valve Control Circuit Performance

This code is triggered when the Engine Control Module (ECM) or Powertrain Control Module (PCM) detects that the intake valve control mechanism for cylinder 1 is not performing within expected parameters.

Unlike code P3401, which suggests an open circuit, P3402 indicates a performance problem—meaning the circuit is functional but not behaving as intended.

This problem could stem from electrical issues, mechanical malfunction, or hydraulic flow inconsistencies, all of which can impair proper cylinder deactivation in cylinder 1.

Understanding Cylinder Deactivation Systems

In engines that feature cylinder deactivation technology, specific cylinders are temporarily shut down under light load conditions (such as highway cruising). This helps reduce fuel consumption by running only half the engine’s cylinders.

To disable a cylinder:

- The ECM halts fuel injection and spark to that cylinder.

- It also disables valve motion using special lifters and oil control solenoids, effectively stopping air and fuel flow.

- When extra power is needed (such as during acceleration), the system reactivates the cylinders. This process must be fast and seamless, and relies on precise oil pressure, electrical control, and component condition.

P3402 Cylinder 1 Deactivation/Intake Valve Control Circuit Performance

Which Vehicles Use This System?

The P3402 code is commonly found in vehicles equipped with Active Fuel Management (AFM), Displacement on Demand (DoD), or Variable Cylinder Management (VCM) systems. Common manufacturers include:

- Chevrolet / GMC (Silverado, Tahoe, Suburban, Sierra, Yukon, etc.)

- Cadillac (Escalade, CTS)

- Honda (Pilot, Odyssey, Ridgeline with VCM engines)

- These systems typically deactivate 4 cylinders on V8 engines and 3 on V6 engines during low load conditions.

Symptoms of P3402

When code P3402 is triggered, you may observe one or more of the following symptoms:

- Illuminated Check Engine Light (CEL)

- Decreased fuel economy

- Engine vibration or rough idle

- Reduced power output

- Ticking or tapping noise from the engine

- Misfire symptoms (though misfire codes may not always be present)

In some cases, no noticeable symptoms occur beyond the illuminated CEL, making it easy to overlook if diagnostics are not performed.

P3402 Cylinder 1 Deactivation/Intake Valve Control Circuit Performance

Causes of Code P3402

Several possible conditions can result in the P3402 code. The most common include:

1. Faulty Intake Valve Control Solenoid (Cylinder 1)

A malfunctioning or sticking oil control solenoid may fail to regulate oil flow needed to collapse the deactivation lifter on cylinder 1.

2. Electrical Problems

- Corroded, frayed, or broken wiring

- Poor connector engagement

- Voltage drop due to poor grounding

Any of these may result in improper solenoid operation.

3. Dirty or Low Engine Oil

Oil is the hydraulic fluid used in activating the deactivation system. If the oil is old, dirty, sludgy, or low in volume, it may fail to activate or deactivate the lifters as required.

4. Oil Pressure Problems

Low or inconsistent oil pressure can prevent proper system operation, particularly when transitioning between active and inactive cylinder modes.

5. Faulty Cylinder 1 Deactivation Lifter

If the lifter or related valvetrain components are worn or mechanically damaged, the intake valve may not respond properly even if the solenoid is working.

6. ECM/PCM Malfunction

Though rare, a failing control module might send incorrect commands or misread sensor data related to cylinder deactivation.

Diagnostic Steps for P3402

Properly diagnosing P3402 involves systematically checking the electrical, mechanical, and hydraulic systems. A professional-grade scan tool is recommended.

Step 1: Check for Additional Codes

Retrieve all stored and pending DTCs.

Codes like P0521 (Oil Pressure Sensor Range/Performance) or P3400 (Bank 1 Deactivation Fault) may provide context.

Step 2: Visual Inspection

Inspect the wiring harness around the valve cover and solenoid connector for visible damage or oil contamination.

Ensure connectors are secure.

Step 3: Test the Intake Valve Control Solenoid

Use a multimeter to check resistance (typically 5–20 ohms).

Command the solenoid on/off with a scan tool to ensure responsiveness.

If possible, apply 12V directly to check for solenoid activation.

Step 4: Check Oil Condition and Pressure

Verify that the engine oil is clean, full, and of the correct viscosity.

Use a mechanical oil pressure gauge to compare live pressure readings with factory specifications (usually ~30–60 PSI at idle when warm).

Step 5: Inspect Cylinder 1 Lifter and Valvetrain (Advanced)

If all above checks pass but issues persist, a physical inspection of the lifters, rocker arms, and pushrods may be needed.

This often involves removing the valve cover or intake manifold.

P3402 Cylinder 1 Deactivation/Intake Valve Control Circuit Performance

How to Fix DTC P3402

Depending on the diagnostic findings, here are common repair strategies for resolving P3402:

1. Replace Faulty Intake Valve Control Solenoid

If electrically dead or stuck, replacing the solenoid often resolves the issue.

These solenoids are typically located on the valve cover or inside the valley cover assembly.

2. Repair or Replace Wiring and Connectors

Damaged harnesses or corroded connectors must be repaired.

Use dielectric grease to prevent future corrosion.

3. Change Engine Oil and Filter

Replace with the OEM-specified oil viscosity (e.g., 5W-30 or 0W-20).

Clean oil ensures proper hydraulic function of the AFM/VCM system.

4. Replace Faulty Lifter or Valvetrain Parts

If a deactivation lifter is seized or not functioning correctly, it must be replaced.

This may require removal of the cylinder head, making it a labor-intensive repair.

5. Update or Replace ECM/PCM (If Necessary)

If the control module is not commanding the system correctly despite functional components, software updates or replacement may be needed.

P3402 Cylinder 1 Deactivation/Intake Valve Control Circuit Performance

Preventing P3402 in the Future

To reduce the chances of this code reoccurring:

- Maintain regular oil changes with high-quality oil.

- Avoid using the wrong oil viscosity, especially in engines with AFM/VCM systems.

- Inspect wiring and solenoids periodically, especially during engine service.

- Address oil pressure or performance issues early, before they lead to more serious engine damage.

Conclusion

DTC P3402 points to a performance problem in the intake valve control circuit for cylinder 1, part of the cylinder deactivation system used in many fuel-efficient engines.

While not immediately catastrophic, ignoring this issue can lead to reduced fuel economy, engine wear, and eventually, mechanical damage.

By understanding the role of the intake valve control solenoid, keeping the engine properly maintained, and using proper diagnostic tools, most issues leading to P3402 can be identified and resolved efficiently.

- Custom Lifted Diesel Trucks for Sale - December 20, 2025

- New Lifted Diesel Trucks for Sale - December 19, 2025

- Old Lifted Diesel Trucks for Sale - December 18, 2025